Tank Drain Systems

W.E. Couplings Ltd have been established since 1991, specialising in the supply of bespoke hose and fittings.

W.E. Couplings manufacture and stock a wide range of industrial rubber and PVC hose in long lengths,

which can be assembled to your individual requirements.

In aboveground floating roof storage tanks for fuel & oil, etc., there must be a method of removing rainwater from the dynamic roof. W.E. Couplings Ltd design and manufacture a range of systems for this purpose, from economical flexible rubber hose systems, to long-lifetime stainless articulated pipework systems. We have supplied these systems to storage tank builders and tank farm maintenance teams worldwide for over a decade, and continue to offer a fast and reliable turnaround on a quality range of drain systems.

Each storage tank can present a different challenge, and require a bespoke solution for drainage.

Following API650 specification for fuel storage tanks, some customers opt to have an extra 'Stainless Steel Armour' cover added to the drain hose system.

Draining rain water from an external floating roof is important to make sure the external floating roof will not build up too much water on top, which could even cause sinking of the roof in the worst cases. W.E.Couplings Ltd offer an economic solution by manufacturing rubber tank drain hoses specifically for this application, from a material compatible with the stored medium - i.e. Nitrile rubber or for more aggressive mediums a high quality Viton®. The major advantage of a hose is that it has a minimum number of connections, therefore eliminating much of the potential problems with other drain systems. As the drain hose is a complete system, including the connections, the lead ballast cable system is installed prior to dispatch. Each hose is individually hydrostatically tested prior to shipment, to ensure its performance. As a result of the flexible nature of the drain hose, it will even be able to deal with frozen rain water inside.

Applications:

Flexible hose assemblies for immersion inside storage tanks to drain rainwater from the floating roof. Specially compounded covers are used to resist immersion in high aromatic or corrosive liquids.

Lining:

Smooth bore, mandrel built, Nitrile (NBR) or Viton® (FKM) lined hose, depending on the type of hose specified or required

Reinforcement:

Textile cord reinforcement with a high tensile stainless alloy wire helix,

to resist collapsing by external pressure when fully immersed

Pressure:

Although these hoses are rainwater drains experiencing low pressures

when in use, the integrity of the hose assemblies is checked, after

ballasting, by testing to 10 bar with water and vacuum testing to -0.85 bar.

Full and detailed test and material certificates are supplied as a standard.

Covering:

Smooth wrapped finish in the following materials:

PVC/NBR Nitrile Aromatic content up to 80%

Viton® Aromatic content up to 100%

(Tolerance to hazardous environments high in hydrocarbon content)

Lead ballast and branding:

Each hose assembly incorporates a permanently attached lead covered stainless steel cable to give the hose a close-to-neutral bouyancy in the stored product. This ensures that even a small amount of rainwater brings the bouyancy of the hose system to negative, triggering the outflow of rainwater. It then returns to floating underneath the ceiling - away from the potential damage area that the ends of the roof legs present. A longitudinal white stripe is permanently branded on the cover of each hose to ensure correct alignment. All hoses are supplied electrically continuous. Clamps and chains with a quick-link for an attachment to the ceiling are also supplied.

Flanges:

Generally mild steel nipples with fixed ASA150 R/F flanges are supplied. Other flanged drillings and material types are available, including swivel flanges. The ballast is permanently attached internally to the top fitting.

We also design and manufacture our own versions of the traditional articulated system, that incorporate greater lateral stability and fold flatter than other designs, to allow the roof to get lower and therefore potentially save many barrels of expensive Jet fuel, or whatever fluid is being stored in the tank.

Animation of a flexible roof drain hose system

Stages of the flexible roof drain hose in operation, with roof leg protectors installed

Fuel storage tanks

Floating roof storage tank

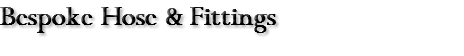

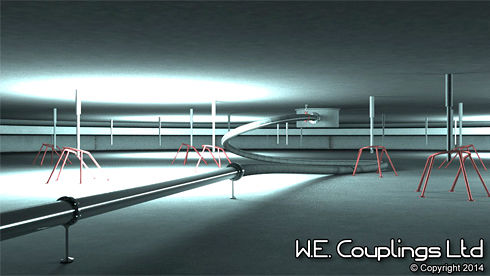

2D CAD & 3D Design to simulate articulated drain system working in tank

Animation of quadruple flexible hose drain system in a huge 110 Meter diameter fuel storage tank

Stainless Steel overbraid armour on 6" Tank Drain Hoses

Articulated 4 swivel joint roof drain system

Articulated 4 swivel joint roof drain system, reinforced by supporting chain

3D Render of the W.E. Couplings 'tri-lobe' articulated drain system

Flexible drain hose with roof leg protectors to help prevent damage

Leg protectors, installed to help prevent the hose catching on the roof legs

Animation of a fully articulated roof drain system, reinforced by a chain

Detail of the roof sump with non-return valve, and chain supporting top of

Stages of the flexible roof drain hose in operation, with roof leg protectors installed

Flexible drain hose with stainless steel outer armour

Feel free to browse our extensive product range and projects

using the links on the floating menu or click here

Please contact us for further information or assistance:

W.E. Couplings Ltd

Units 2 & 3B Grimeford Industrial Estate

Grimeford Lane, Anderton

Near Chorley, Lancashire PR6 9HL

Contact US

Units 1,2,3b Grimeford lane ind. EST.

Grimeford lane, anderton, chorley

LANCASHIRE, ENGLAND PR6 9HL

Tel: +44 (0)1257 475101

FAX: +44 (0)1257 482424

Powered by CSS : Designed for W.E. Couplings Ltd by Katie Garbett & James Nevins